Abdullah Akgöz, CEO of New Tech Makine, answered the questions of Sleeptech magazine editor Furkan Akar about production, export, R&D and innovation.

Akgöz, in the interview with our magazine editor, talking about the production capacity, innovative features of the machines they produced and export policies, gave the following statements about the position of New Tech’s in the mattress industry; “The awareness of our brand is increasing. We started upgrading with the quality machines we made and the after-sales services we provided. Not for capacity but according to the quality of machine we produced, we witness that our brand has started to take its place alongside the well-established brands in Turkey.”

Can you mention the products you made for the mattress components sector and their features?

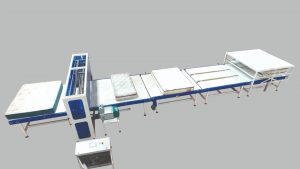

We are producing state-of-the-art machines that will facilitate the manufacture of mattress manufacturers. Those are multi-needle quilting machines, single and double-needle quilting machines, bed edge closing machines, automatic gluing machines for mattress manufacturers who want to do mass production and production lines with a conveyor system working in sync with it, mattress packaging machines, which is the machine group having increased the most of its type recently. Three different roll packaging machines are being produced based on the need for the roll packaging machine, which is a trend in this group. We are producing semi-automatic roll packaging machine for small and medium-sized firms, fully automatic roll packaging machine for medium and large-sized firms, and finally, the folding fully automatic roll packaging machine preferred by special large-size mattress manufacturers.

Can you mention your R&D and innovation studies?

Our policy, as New Tech Makine, is to continuously improve our R&D, innovation and production line in order to provide better quality products and services to our customers. We are developing machines in terms of software and mechanics, making them more compact and faster. In this context, it provides space and time advantages to mattress manufacturers. With the developing technology, we are developing new products offering rational solutions to the changing needs of our customers. We are carrying our existing products forward with this technology.

Can you mention your export range and foreign trade marketing tactics?

We are exporting to 25 different countries in 5 continents. As a foreign trade marketing activity, we can list these as being in constant communication with customers by organizing marketing trips, participating in fairs held abroad and in the country, and advertising on the internet. Recently, we have been actively using social media and YouTube channel.

What is your annual production capacity? What do you expect by the end of the year?

Our average annual production capacity of the machines in the group of machines I mentioned above is 50. By the end of the year, we aim to increase the capacity to 60-65 machines with the expectation of 25% capacity increase.

Can we get your thoughts on the current situation of Turkey in the bearing components sector and what your predictions will be about the developments in the short and long term?

I think that the current situation of Turkey in the bearing components sector is positive and it will be even better for the future. One of the factors that will affect this the most is the increase in costs in China, and high freight prices, and those have reduced the attractiveness of China. It is not the time to open factory in China and India and make cheap production. With the combination of these factors, Turkey has come to an attractive place in the mattress sector. I think it will keep its charm in the long term.

How do you position yourself in the sector as New Tech?

As New Tech, we always give priority to the customers and we take care to understand their needs in order to provide leading machine technologies and services to our customers. Although we are a 2-year-old company, we believe that we have started to reap the benefits of our approach to our customers in this way. The awareness of our brand is increasing. We started to come to better points with the quality machines we made and the after-sales services we provided. According to the quality of the machine we produce, not in terms of capacity, we see that our brand has started to take its place alongside the well-established brands in Turkey.

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials