Established at the beginning of 2013 by two young entrepreneurs, Format company experienced a remarkable growth. Emphasizing on their production process that is built on recycling of wasted materials, Mustafa Ozenc, a partner of the company informed about new projects of their company.

On the foundation of the company

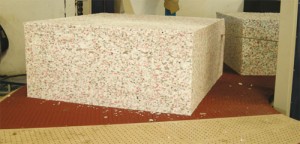

It seemed to me that, establishing an independent and complete foam factory from starch will be highly costly. So I decided to build a part of complete operation. We decided to establish a partnership with Abidin Sezgin. We bought machinery from domestic manufacturers. In our factory of 3500 sqm we now produce bondex, having a ecological certificate from the ministry of environment. The new regulation of the ministry forces foam factories to deliver all by-products to companies similar to us. Thus we recycle them to form again to be used in the mattress industry.

On products that company produces

We cut bondex foams at 50 to 60 dns thicknesses. It improves our product quality. In this way, side frames and plate foams are becoming better and more durable. Our product portfolio is composed of bondex foams of 14 to 32 dns range.

On exports and raw material procurement

On exports and raw material procurement

We procure our raw material needs from abroad, from Germany and America. Since foam is a voluminous product it is hard to export them. O

n investment as a new factory

Since we are a new company, we invest in our business. We are considering to develop new projects that aim to the same market.

We thank you, and your publication Sleepwell, for your efforts and contributions in improving the communication in mattress industry. We wish you and all your partners success.

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials