By HERMAN MOUREAU & JORIS PITTEVILS* MIKE ANDERSON* YUN-SHAN LIU*

ABSTRACT

Polyurethane visco-elastic memory foam mattresses can improve sleep by reducing pressure points. This can help to reduce tossing and turning, leading to a deeper sleep. However, some sleepers end up “sleeping hot”, waking up sweating1,2 when using a visco memory foam mattress. In a bid to make mattresses more comfortable, Huntsman has developed RUBIFLEX® Cocoon polyurethane- based foam technology, which can be used to manufacture a cooler, more breathable and flexible foam for bedding, furniture and seating applications. The RUBIFLEX® Cocoon foam system is designed to significantly enhance comfort by reducing the build-up of heat and humidity in foam mattresses, pillows and seat cushions, caused by the body when it is at rest5.

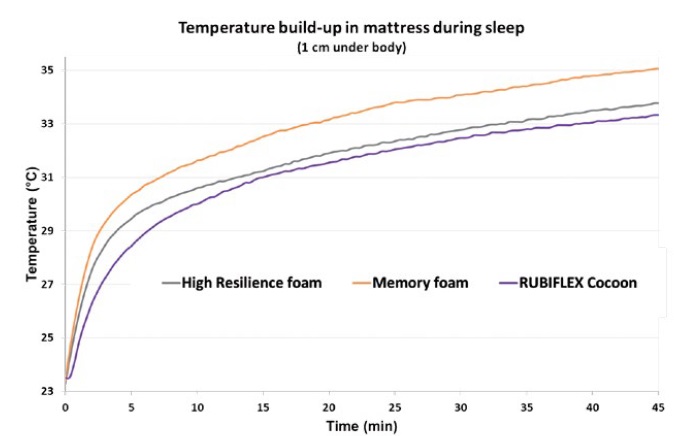

Huntsman, in close cooperation with customers, has developed a laboratory procedure to benchmark mattress foams, with the goal of keeping the benefits of reducing pressure points, while addressing “sleep hot” concerns. This paper describes Huntsman’s efforts to measure the pressure distribution across the body of a sleeper over time. More interestingly, it will also describe how to measure the hygrothermal behavior of the microclimate between the participant and the mattress, meaning the change in temperature and the dissipation of humidity in the microclimate over time. We have seen a reduction of 1.5 – 2 °C in the microclimate temperature on our “Cocoon” foams indicating a “cooler” and thus a more relaxed sleep.

INTRODUCTION

Though slightly lagging behind Europe, visco-elastic polyurethane foams are getting more popular than ever in North America. It was estimated that 1 out of 5 mattresses sold in United States was a full polyurethane foam mattress in 20123. A recent market survey about the types of mattresses consumers would likely buy next showed that up to almost 30% would choose a full memory foam mattress (“Furniture Today”4). The use of polyurethane foams is also increasing in “hybrid” mattresses (adding a layer of polyurethane memory foam to improve comfort in conventional box-spring mattresses). In general, visco-elastic foams are used as a comfort layer to provide a good sleep for consumers because of its slow recovery characteristics after compression, the foam envelopes the body, giving a sensation of being cradled. The foam shields one sleeper from the other, so a sleeper is less affected by the person sleeping next to them. The comfort layer of a mattress is of essential importance for the thermo-physiological quality of the body supporting structure and enhances the sleep comfort of a mattress5.

The technology to produce visco-elastic polyurethane foams has evolved rapidly in the past 10 years. However, visco-elastic foams are yet to be perfect. For example, some sleepers end up “sleeping hot”, waking up sweating1,2 when using a visco memory foam mattress. Slabstock producers have introduced new technologies such as gel-infused memory foams to reduce heat built-up concerns. Hence there is still a great desire to develop innovative products to address the above-mentioned issues. In a bid to make mattresses more comfortable, Huntsman has developed RUBIFLEX® Cocoon polyurethane- based foam technology6,7, which can be used to manufacture cool, breathable, flexible foams for bedding, furniture and seating applications. RUBIFLEX® Cocoon foam system is designed to significantly enhance comfort by reducing the build up of heat and humidity in flexible foam, caused by the body when it is at rest. Huntsman, in close cooperation with customers, has developed a laboratory screening method to benchmark mattress foams, with the goal of keeping the benefits of reducing pressure points, while addressing the “sleep hot” concerns. The new screening method was able to measure the pressure distribution across the body of a sleeper over time. We are also able to measure the hygrothermal behavior of the microclimate between the participant and the mattress, meaning the change in temperature and the dissipation of humidity in the microclimate over time. We have seen a reduction of 1.5 – 2 °C in the microclimate temperature on our “Cocoon” foams indicating a “cooler” sleep.

RESULTS AND DISCUSSION

Combining pressure-relieving property of memory foams and the support property of high-resilience foams, RUBIFLEX® Cocoon foams provide excellent support and good pressure distribution – cradling the body and minimizing pressure points to maximize blood flow and promote good sleep. By designing with a good balance of hydrophilic and hydrophobic segments, the polymer structure of RUBIFLEX® Cocoon foam system facilitates water vapor permeability and humidity transmission. Temperature- mapping tests show that the temperature build up in foams based on RUBIFLEX® Cocoon technology is more than 1.5ºC lower than in a comparable memory foam solution. Foams based on RUBIFLEX® Cocoon technology have a good initial hand-feeling and work well in most climates. RUBIFLEX® Cocoon-based foams also have an excellent wet compression set and good tear strength compared to memory foams. Conforming to LGA and CertiPUR® standards, they meet low volatile organic compounds (VOCs) requirements.

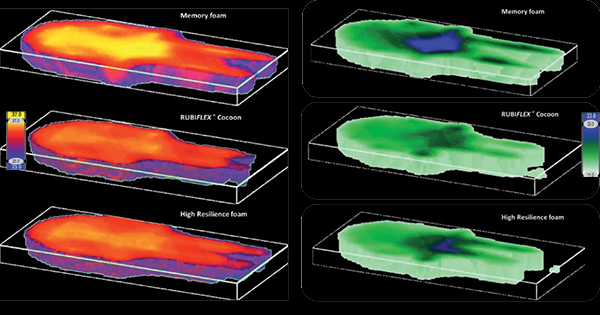

While the pressure mapping of a visco foam mattress is known in the industry, the measure of hygrothermal behavior of a person sleeping on a mattress is relatively new. Little is known in public literature about the transmission of moisture and heat through mattresses. In collaboration with the test lab Custom8 (a spin-off lab from the Biomechanic Department of the University of Leuven, Belgium, http://www.custom8.be/), Huntsman was able to develop a method to bench mark sleep comfort in terms of pressure distribution, as well as the hygrothermal behavior of the microclimate between the participant and the mattress. The hygrothermal behavior of the microclimate refers to the change in temperature of the microclimate and the dissipation of humidity in the microclimate over time. The μCliMat is a patented sensor mat from Custom8 containing temperature and humidity sensors specifically designed for the use in layered flexible materials such as mattresses and car seats. With the μ-cliMat sensors, two full size mats were constructed to be able to do measurements with the test person of 80kg, as shown in Figure 1. 2.5 cm of foam was placed on top of a 15 cm core foam. A μ cliMat sensor was placed on the foam, followed by a 1.5 cm piece of foam, another μ cliMat sensor, and a 1 cm layer of foam. Afterwards a 3D image was created by using the μ-CliMon software provided by Custom8. The measurements took one hour. It started with one-and-a-half minutes of measuring without test person, followed by forty-five minutes with the test person on the mattress and then fifteen minutes cooling down without test person.

Figure 1. The set up of hygrothermal measurements

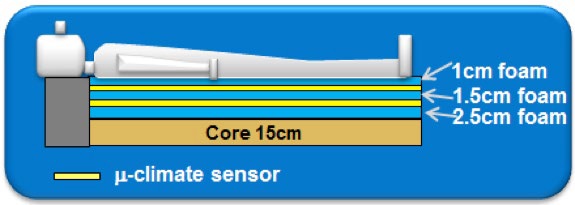

The temperature mapping of three types of foams with a real person is shown in Figure 2.

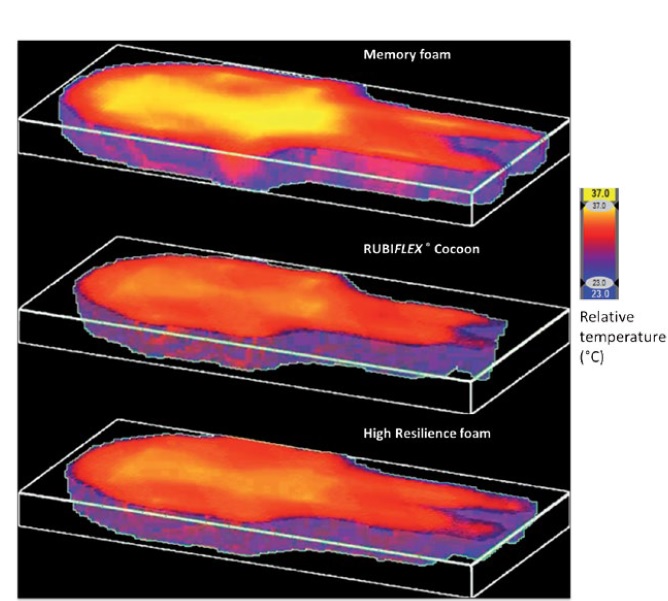

The temperature build-up of three tested foams with real person is shown in Figure 3.

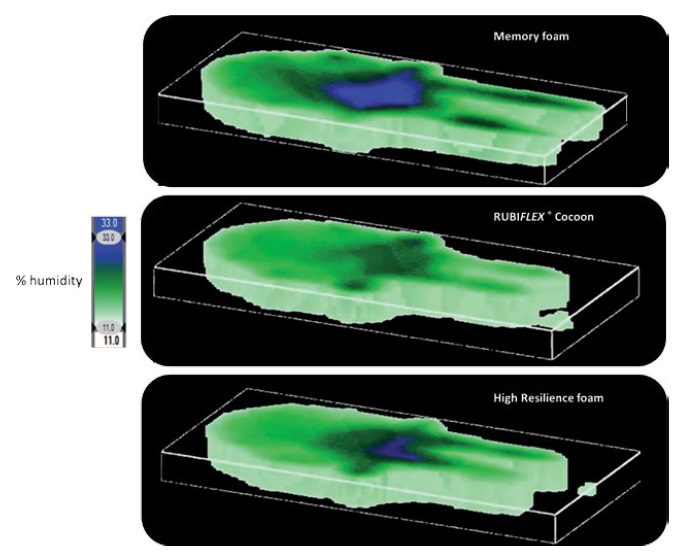

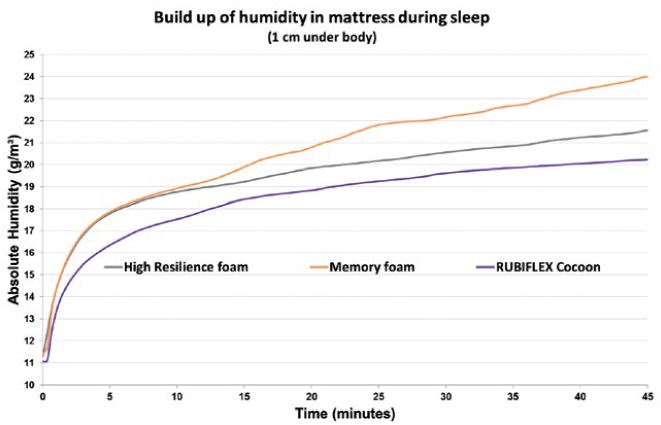

Three types of foams (RUBIFLEX® Cocoon, visco and HR foams) were tested as shown in Figures 1-3. The data shows that temperature build-up in RUBIFLEX® Cocoon foam has been shown to be more than1.5oC lower than memory foam. In the same setup, humidity build-up was also tested and the results also show that RUBIFLEX® Cocoon foam has less humidity build-up than either visco or HR foam (Figure 4 and Figure 5).

Figure 4. Absolute humidity mapping in a mattress during sleep measured 1cm under the body after 45 minutes

Figure 5. Humidity build-up in RUBIFLEX® Cocoon foam against visco and HR foams

As shown in Figure 4 and Figure 5, the RUBIFLEX ® Cocoon foam demonstrated a much slower humidity build-up compared to either HR or visco foams.

CONCLUSION

Huntsman has effectively developed a method to measure hygrothermal properties that can better benchmark various types of flexible foams. The test results showed that RUBIFLEX® Cocoon foams can better dissipate heat and humidity than either visco or HR foams in a mattress. These promising data demonstrate that the RUBIFLEX® Cocoon foams can not only provide support and pressure distribution, but also excellent heat and humidity dissipation properties which can lead to a more relaxed sleep for consumers.

EXPERIMENTAL

All the foams presented in this paper were produced with a Cannon- Viking pilot slabstock machine. This machine is equipped with traversing nozzle laydown dispensing capabilities. All the physical tests were carried out using ASTM ASTM D 3574 A-F methods. The hygrothermal testing was done in collaboration with Cutom8. 3D images were created by using the μ-CliMon software provided by Custom8.

TRADEMARKS

RUBIFLEX® is registered trademark of Huntsman Corporation or an affiliate thereof in one or more, but not all countries. CertiPUR-US® is a registered certification mark of Alliance for Flexible Polyurethane Foam, Inc., a not-forprofit organization.

ACKNOWLEDGEMENT

We are thankful to Mr. Glyn Davies, Mr. Johan Macken and many other colleagues at our R&D center in Everberg, Belgium for their efforts carrying out foaming, physical testing and numerous contributions to this project.

#SleepComfort, #BenchmarkingSleep, #BeddingIndustry, #Sleephot, #SleepHotorNot, #Mattress, #Comfort, #FoamMattresses

REFERENCES:

1) Memory Foams –pros and cons, The Mattress Underground

2) “Top Ten Problems With Memory Foam ”

3) Yun-Shan Liu, Glyn Davies, Katherine Piasecki, CPI Polyurethanes 2012 Technical Conference Proceedings, “CertiPUR-US® Compliant MDI Flexible Polyurethane Foams” , and the reference cited therein.

4) “Furniture Today”, by David Perry, 2013-05-06

5) Thomas A. Krouskop; Phillips S . Nobel; Jim Brown; Rebecca Marburger, Journal of Rehabilitation Research and Development, Vol. 23(3), July 1986, p33-39, “Factors affecting the pressure-distributing properties of foam mattress overlays”

6) The Urethane Blog

7) RUBIFLEX® Cocoon technology is patent pending, WO 2013/014143 Al

“This information may contain copyrighted material, the use of which has not always been specifically authorized by the copyright owner. In accordance with Title 17 U.S.C. Section 107, the material in this presentation is being used for nonprofit educational purposes and will not be made available for distribution. ACC believes this constitutes a ‘fair use’ of any such copyrighted material as provided for in section 107 of the US Copyright Law. For more information, go to:

https://urldefense.proofpoint.com/v2/url?u=http-3A__www.copyright.gov_title17_92chap1.html-23107.If&d=CwIGaQ&c=XEmjTyjfAPcP2RtAp-6FGA&r=pGFVzFjEdfKr03CNSbIgUZ-HnpJo9eseoj85S1z-7wE&m=pSAjIC2iPRzOrKOmlhF5pbhxuQBMfWErPt93H4O3dXU&s=xUQaLq60gcVGiJggeG0aIWCtmQQV6sf8GXsdzANbvKw&e=

copyrighted material from this presentation is further used for purposes that go beyond “fair use,” permission from the copyright owner must be obtained.”

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials