As a key exporter to Europe’s top brands, Aydın Tekstil continues to solidify its position in the industry with top-tier production, cutting-edge designs, and a strong commitment to sustainable manufacturing. By ramping up investments and setting its sights on new markets, the company is determined to stay ahead of the curve in global competition.

Founded in 1957, Aydın Tekstil has grown into a powerhouse, supplying major brands worldwide with its extensive product range. Operating with a workforce of 3,000 in a massive 500,000-square-meter production facility, the company stands as Europe’s largest manufacturer of upholstery fabric, mattress ticking and decorative carpet, exporting to over 120 countries with more than 65 years of expertise.

In our conversation, Ayça Şengül, Regional Sales and Marketing Manager at Aydın Tekstil, shed light on the company’s growth journey, sustainability efforts, and future ambitions.

65 years of steady growth and game-changing innovation

Aydın Tekstil is Europe’s largest manufacturer of upholstery fabric, decorative carpets, and mattress fabrics, with exports to over 120 countries and a legacy spanning more than 65 years. How do you evaluate the company’s growth and evolution over the years?

“Aydın Tekstil has been going from strength to strength for over 65 years, fueled by a clear vision and unwavering determination. From day one, our commitment to quality, innovation, and customer satisfaction has been the driving force behind our success. We’ve carved out a solid reputation in the industry and continue to sharpen our competitive edge in the global market.

With our state-of-the-art production facilities and a talented team, we proudly serve leading brands across the globe. By embracing sustainable manufacturing and keeping our finger on the pulse of innovation, we have not only kept up with industry shifts but have also positioned ourselves as a trailblazer in the field.”

Building trust-based partnerships in the European market

You currently export to many of Europe’s top-tier brands. How did these partnerships take shape, and what challenges did you encounter along the way?

“Our journey in the European market started with a rock-solid commitment to quality and reliability. We aligned our production processes with international quality standards, then took things a step further by refining our collection-based manufacturing approach, proving our agility in fast delivery and flexible production. The strong relationships we built with our customers became a cornerstone of our success.

For us, collaboration isn’t just about business transactions—it’s about fostering long-term partnerships. We maintain open lines of communication, frequently touching base with our customers to stay attuned to their evolving needs. Thanks to these trust-based relationships, many of our partnerships have stood the test of time.

To further establish our presence and explore new opportunities, we actively participate in leading international textile fairs. These events are not only a gateway to potential clients but also a great way for us to keep an eye on industry trends and continue refining our innovative production approach.

Of course, breaking into the European market wasn’t a walk in the park. Competition was fierce, and becoming a supplier to global brands meant jumping through hoops to meet their rigorous quality inspections. In our early export days, some clients had sky-high expectations, which pushed us to fine-tune our production lines. We doubled down on our quality control processes and implemented additional checks at various stages of production to leave no room for error.

Another hurdle was keeping pace with Europe’s demand for speed. Major brands expect lightning-fast turnaround times, so we ramped up operational support, optimized our logistics and stock management, and fine-tuned our workflow for maximum efficiency.”

Tailor-made innovation: A customer-centric design approach

Your product range includes upholstery fabric, mattress fabric, carpets, and rugs. What is your approach to designing and producing such a diverse collection?

“We take an innovative and customer-focused approach to both design and production. Since our portfolio caters to multiple applications—such as carpets, rugs, upholstery fabrics, and mattress textiles—we develop tailored strategies for each category.

When it comes to design, we keep our ear to the ground, closely tracking industry trends and customer demands. For example, upholstery fabrics need to strike a balance between durability and aesthetics, while mattress fabrics must prioritize comfort and breathability. That’s why our design team crafts collections that are both trend-conscious and highly functional.

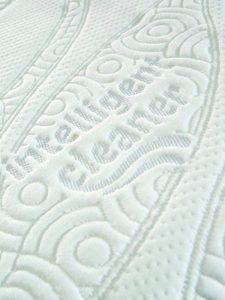

On the production side, we emphasize flexibility, top-notch quality, and cutting-edge innovation. We continuously refine our processes by integrating advanced manufacturing technologies and sustainable materials. For instance, in carpet and rug production, we blend traditional weaving techniques with modern technology, while in mattress fabrics, we use antibacterial yarns to enhance hygiene and durability. Our goal is to deliver smart, creative solutions that tick all the boxes for our customers.”

Bringing Anatolia’s rich heritage into the modern era

You seamlessly blend Anatolia’s vibrant color and pattern heritage with modern trends to create market-specific designs. How do you strike that balance, and how does your design team approach this process?

“At Aydın Tekstil, we take great pride in fusing Anatolia’s deep-rooted cultural legacy with contemporary design concepts, offering products tailored to each market’s unique tastes. Striking this balance requires a multi-faceted approach, where we embrace both traditional aesthetics and global trends.

Our design team delves into Anatolian motifs, color palettes, and weaving techniques, then reinterprets them to meet modern consumer expectations and market preferences. For instance, the European market leans toward minimalist, understated tones, while the Middle Eastern market favors bold colors and intricate designs. We fine-tune our collections accordingly.

Sustainability and innovation also play a central role in our design philosophy. We incorporate recycled yarns and natural dyes, ensuring that our products are as eco-friendly as they are stylish.

Keeping up with trends and listening to customer feedback are essential for us. Our design team frequently attends international fairs to stay ahead of the curve and bring fresh ideas to the table.”

What steps are you taking in terms of sustainability and innovation? Can you share some insights into your eco-friendly production practices?

“Sustainability isn’t just a buzzword for us—it’s a long-term responsibility. That’s why we are constantly rolling out projects and innovative practices to make our production processes greener.

We integrate recycled and organic raw materials into our manufacturing, using GOTS- and OEKO-TEX-certified organic cotton and recycled polyester. Our production facilities are also optimized for energy efficiency, incorporating renewable energy sources and water-saving dyeing and washing technologies. Additionally, we are heavily invested in waste management and circular economy initiatives.

On top of that, we actively participate in international textile fairs and R&D projects to stay ahead of the pack and contribute to the future of sustainable textiles.”

How do you approach customer satisfaction and service quality? How do you manage customer relationships and handle feedback?

“At Aydın Tekstil, customer satisfaction isn’t just a box to tick—it’s the backbone of our business. We believe in building strong, long-lasting relationships through transparent communication and a proactive mindset.

We pride ourselves on fast response times and tailor-made solutions. Through regular meetings, trade fair participation, and collection development, we keep a finger on the pulse of our customers’ ever-changing needs.

Customer feedback is a goldmine for continuous improvement. We meticulously analyze client input and quality assessments, using them as a springboard for innovation and refinement.”

Innovative growth and a bold vision for the future

What are your future goals and projects? Can you share Aydın Tekstil’s short- and long-term strategies for growth?

“Our roadmap for the future is built on three pillars: sustainable growth, innovation, and expanding our footprint in the global market.

In the short term, we’re focused on increasing production capacity and boosting efficiency. We’re also expanding our product range with more eco-friendly materials, strengthening our sustainable collections.

Long-term, our game plan includes expanding our international presence, forging new strategic partnerships, and launching joint projects with leading brands, particularly in the U.S. and Europe. At the same time, we’re pushing the boundaries of R&D, with a strong focus on pioneering next-generation textile technologies and groundbreaking industry advancements.”

***

Aydın Tekstil, küresel pazarda büyümeye devam ediyor

Avrupa’nın önde gelen markalarına ihracat yapan Aydın Tekstil, kaliteli üretimi, yenilikçi tasarımları ve sürdürülebilir üretim anlayışıyla sektördeki konumunu güçlendiriyor. Şirket, yeni pazarlara açılma hedefleri doğrultusunda yatırımlarını artırarak küresel rekabette daha güçlü bir oyuncu olmayı hedefliyor.

1957 yılında kurulan Aydın Tekstil bugün geniş ürün yelpazesiyle dünya genelindeki önemli markalara üretim yapıyor. 500.000 metrekare kapalı alanda 3000 kişiyle üretim yapan Aydın Tekstil, 120’den fazla ülkeye ihracatı ve 65 yıla aşkın tecrübesi ile Avrupa’nın en büyük döşemelik kumaş, dekoratif halı ve yataklık kumaş üreticisidir.

Kendisiyle yaptığımız söyleşide Aydın Tekstil Bölgesel Satış ve Pazarlama Müdürü Ayça Şengül, firmanın büyüme süreci, sürdürülebilirlik çalışmaları ve geleceğe yönelik hedefleri hakkında önemli açıklamalarda bulundu.

65 yılı aşkın istikrar ve yenilikçi büyüme

Aydın Tekstil, 120’den fazla ülkeye ihracatı ve 65 yıla aşkın tecrübesi ile Avrupa’nın en büyük döşemelik kumaş, dekoratif halı ve yataklık kumaş üreticisi. Bu süreçte şirketinizin büyümesini ve gelişimini nasıl değerlendiriyorsunuz?

“Aydın Tekstil, 65 yılı aşkın tecrübesi ile her sene sağlam bir vizyon ve kararlılıkla büyümesini sürdürmektedir. Kuruluşumuzdan itibaren kaliteye, yenilikçiliğe ve müşteri memnuniyetine verdiğimiz önem, şirketimizin sektörde kendisine sağlam bir yer edinmesini sağladı. Küresel pazarda her geçen sene rekabet gücünü arttırarak daha da ileriye gitmeye devam etmektedir. Bugün, modern üretim tesislerimiz ve güçlü ekibimizle dünyanın dört bir yanında birçok markaya hizmet vermekteyiz. Bu süreçte sürdürülebilir üretim ve inovasyon odaklı çalışmalarımız sayesinde sektördeki değişimlere uyum sağlayarak gelişmeye devam ediyoruz.”

Avrupa pazarında güvene dayalı güçlü iş ortaklıkları

Şu anda birçok ünlü Avrupa markasına ihracat yapıyorsunuz. Bu markalarla olan iş birlikleriniz nasıl başladı ve bu süreçte ne gibi zorluklarla karşılaştınız?

“Aydın Tekstil olarak, Avrupa’daki müşterilerimiz ile işbirliğimiz kaliteye ve güvenilirliğe verdiğimiz önemle başladı. Üretim süreçlerimizi uluslararası kalite standartlarına uygun hale getirdik. Devamında, koleksiyon bazlı üretim süreçlerimizi daha da geliştirerek, hızlı teslimat ve esnek üretim yeteneklerimizi kanıtladık. Müşterilerimiz ile kurduğumuz güçlü ilişkiler de gelişimimizin temel kaynaklarından biri oldu. İşbirliğimizi sadece ticari bağ olarak görmüyor ve uzun vadeli ortaklıklar kurmaya özen gösteriyoruz. Sık sık gerçekleştirdiğimiz görüşmeler ile onların ihtiyaçlarını ve taleplerini yakından takip ediyoruz. Güvene dayalı bu ilişkiler sayesinde, birçok müşterimiz ile yıllardır süregelen güçlü iş ortaklıkları gerçekleştirdik. Ayrıca, sektörde kendimizi daha iyi tanıtmak ve yeni işbirlikleri kurmak adına pek çok uluslararası tekstil fuarlarına katılıyoruz. Bizim için hem yeni müşteriler ile tanışma hem de sektördeki yenilikleri yakından takip ederek inovatif üretim anlayışımızı güçlendiriyoruz.

Tabii ki, bu süreçte birçok zorlukla karşılaştık. Avrupa pazarına açıldığımızda rekabet oldukça yoğundu ve global markaların tedarikçisi olabilmek için sıkı kalite denetimlerinden geçmemiz gerekti. Özellikle, ilk ihracat sürecimizde bazı müşterilerin kalite beklentilerini tam olarak karşılayabilmek için üretim hatlarımızda yeniden düzenlemeler yapmak durumunda kaldık. Kalite kontrol süreçlerini güçlendirmek ve hatayı minimuma indirebilmek için üretim aşamalarımıza ek denetimler ekledik. Diğer bir zorluk ise hızlı üretim ve teslimat beklentileri ile başa çıkmak oldu. Avrupa’daki büyük markalar, siparişlerini kısa sürede almaya alışkın olduğu için, üretim süreçlerimizi hızlandırmak adına operasyonel destekleri arttırdık; lojistik süreçlerimizi ve stok yönetimimizi daha işlevsel hale getirerek daha verimli bir süreç yönetimi sağladık.”

Her ürüne özel yenilikçi ve müşteri odaklı tasarım

Ürün portföyünüzde döşemelik kumaş, yatak kumaşı, halı ve kilim gibi çeşitli ürünler bulunmaktadır. Bu geniş ürün yelpazesinin tasarım ve üretim süreçlerinde nasıl bir yaklaşım benimsiyorsunuz?

“Hem tasarım hem üretim süreçlerinde yenilikçi ve müşteri odaklı bir yaklaşım benimsiyoruz. Halı, kilim, döşemelik kumaş ve yatak kumaşı gibi birçok farklı kullanım alanlarında ürün grubumuz olması itibariyle her biri için ayrıca özel tasarım ve üretim stratejileri geliştiriyoruz.

Tasarım sürecinde sektör trendlerini ve müşteri taleplerini yakından takip ediyoruz. Örneğin döşemelik kumaşlar için dayanıklılık ve estetiklik ön plandayken, yatak kumaşlarında konfor ve nefes alabilirlik önemli kriterler arasında yer alıyor. Bu yüzden, her ürün grubuna özel olarak tasarım ekibimiz, hem trend odaklı hem de işlevsel çözümler sunan koleksiyonlar oluşturuyor.

Üretim süreçlerimizde ise esneklik, kalite ve inovatif olmasını ön planda tutuyoruz. Modern üretim teknolojilerini ve sürdürebilir malzemeleri kullanarak süreçlerimizi sürekli geliştiriyoruz. Örneğin halı ve kilim üretiminde geleneksel dokuma tekniklerini modern teknoloji ile birleştirirken yatak kumaşlarında antibakteriyel özelliklere sahip özel iplikler kullanıyoruz. Yenilikçi ve yaratıcı çözümler üreterek müşterilerimizin ihtiyaç ve taleplerine yönelik hizmetler ortaya koyuyoruz.”

Anadolu’nun zengin mirasını modern trendlere uyarlayan tasarımlar

Anadolu’nun zengin renk ve desen koleksiyonunu modern trendlere uyarlayarak her pazara özgü ürünler sunuyorsunuz. Bu dengeyi nasıl sağlıyorsunuz ve tasarım ekibiniz bu süreçte nasıl çalışıyor?

“Aydın Tekstil olarak, Anadolu’nun zengin kültürel mirasını modern tasarım anlayışıyla buluşturarak, her pazara özgü yönelikçi ürünler sunmaya önem veriyoruz. Bu dengeyi sağlamak için de çok yönlü yaklaşım takip ederek hem geleneksel desenleri hem de global trendleri yakından takip ediyoruz.

Tasarım ekibimiz, Anadolu’nun otantik desenlerini, renk paletlerini ve dokuma tekniklerini araştırıyor ve ardından bunları modern tüketici beklentilerine ve her pazarın stiline uygun şekilde yeniden yorumluyor. Örneğin, Avrupa pazarında daha sade ve sofistike tonlar tercih edilirken Orta Doğu pazarında canlı renkler ve detaylı desenler öne çıkıyor. Bu doğrultuda koleksiyonlarımızı Pazar dinamiklerine göre şekillendiriyoruz. Ayrıca sürdürülebilirlik ve inovasyonu da tasarım süreçlerimizde ön plana alıyoruz; geri dönüştürülmüş iplikler ve doğal boyalar kullanarak çevre dostu çözümler üretiyoruz.

Bu süreçlerde trend analizleri ve müşteri geri bildirimleri bizim için çok önemli, Tasarım ekibimiz güncel trendleri takip etmek için uluslararası fuarlara katılıyor ve yenilikleri yakından takip ediyor.”

Sürdürülebilirlik ve yenilikçilik konularında hangi adımları atıyorsunuz? Üretim süreçlerinizde çevre dostu uygulamalar ve projeleriniz hakkında bilgi verebilir misiniz?

“Sürdürülebilirlik bizim için sadece bir trend değil aynı zamanda uzun vadeli bir sorumluluk olarak görmekteyiz. Bu yüzden üretim süreçlerimizi çevre dostu hale getirmek için çeşitli projeler ve inovatif uygulamalar geliştiriyoruz.

Geri dönüştürülmüş ve organik hammaddeler kullanarak üretim yapıyoruz. GOTS ve OEKO-TEX sertifikalarına sahip organik pamuk ve geri dönüştürülmüş polyester gibi sürdürebilir malzemeleri koleksiyonlarımıza entegre ediyoruz. Üretim tesislerimizde enerji verimliliğini arttırmak için yenilenebilir enerji kaynaklarına ve su tüketimini azaltan ve boyama ve yıkama teknolojileri kullanıyoruz. Ayrıca atık yönetimi ve döngüsel ekonomi uygulamalarına odaklanıyoruz. Son olarak, uluslararası tekstil fuarlarına ve sektörel Ar-Ge çalışmalarına aktif katılıyoruz.”

Müşteri memnuniyeti ve hizmet kalitesi konusunda nasıl bir politika izliyorsunuz? Müşterilerinizle olan ilişkilerinizi nasıl yönetiyorsunuz ve geri bildirimleri nasıl değerlendiriyorsunuz?

“Aydın Tekstil olarak, müşteri memnuniyetini yalnızca bir hedef değil, işimizin temelinde yer alan bir değer olarak görüyoruz. Müşterilerimizle güçlü ve uzun vadeli ilişkiler kurmak için şeffaf iletişim ve proaktif işbirliğini anlayışını benimsiyoruz. Müşteri taleplerine hızlı dönüş sağlıyor, özel çözümler geliştiriyoruz. Düzenli toplantılar, fuar katılımları ve koleksiyon çalışmalarıyla onların değişen ihtiyaçlarına adapte oluyoruz.

Geri bildirimi ise gelişimin en önemli kaynağı olarak görüyoruz. Müşteri yorumlarını ve kalite analizlerini detaylı şekilde değerlendirerek süreçlerimizi sürekli iyileştiriyor ve inovasyona yöneliyoruz.”

Yenilikçi büyüme ve geleceğe cesur bir bakış

Gelecek dönem hedefleriniz ve projeleriniz nelerdir? Aydın Tekstil’in kısa ve uzun vadede planladığı yenilikler ve büyüme stratejileri hakkında bilgi alabilir miyiz?

“Gelecek hedeflerimizi sürdürebilir büyüme, yenilikçilik ve küresel pazarda daha güçlü bir konum elde etme üzerine inşa ediyoruz.

Kısa vadede, üretim kapasitemizi artırmak ve verimliliği yükseltmek adına yatırımlar yapıyoruz. Ayrıca sürdürülebilir malzemeler ile ürün çeşitliliğini genişleterek, çevre dostu koleksiyonlarımızı güçlendirmeyi hedefliyoruz.

Uzun vadede ise uluslararası pazardaki varlığımızı genişletmek, yeni stratejik iş birlikleri kurmak özellikle Amerika ve Avrupa’daki büyük markalar ile ortak projeler geliştirmek hedeflerimiz arasında. Bunların yanı sıra Ar-Ge çalışmalarımızı daha ileriye taşıyarak yenilikçi tekstil teknolojilerine odaklanıyor, sürdürebilirlik alanında öncü projeler geliştirmeyi hedefliyoruz.”

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials

SleepTech Magazine Mattress, Accessories, Machinery, Raw Materials